Rolling Bearing Know-How - Basic Live Training - Date on request

Training objective

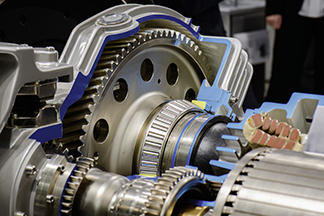

A holistic view of the bearing arrangement - dimensions, load ratings, speeds and operating conditions - is essential for correct bearing selection. By recognising the interactions, quality and service life can be sustainably improved to optimise the performance of the overall system.

Content of training

Operating behaviour of rolling bearings

Bearing clearance, operating clearance

Load distribution in the bearing

Hertzian pressure in the rolling bearing

Subsurface stresses

Rigidity and deflection behaviour

Load ratings

Speeds

Friction and heating

Rolling bearing lifetime

Kinematics of the rolling bearing components

Determining the rolling bearing for an adjusted bearing arrangement according to the catalogue

Determination of axial clearance for universal angular contact ball bearings

Axial load capacity of cylindrical roller bearings

Target audience

Engineers

Category

Rolling and Plain Bearings - Principles

Training requirements

Ball Bearings - Basic Training | FUNDAMENTALS

Roller Bearings - Basic Training | FUNDAMENTALS

Special Bearings - Basic Training | FUNDAMENTALS

Training duration

Further information

For live on-site training courses, please bring your personal notebook or tablet with you.